At first touch, it feels like a contradiction.

A Chyangra pashmina scarf, featherlight and almost liquid in the hand, should not exist. Not with that softness. Not with that warmth. Not with that quiet strength. Not when you consider where it comes from.

Because this fabric is not born in comfort.

It is born in punishment.

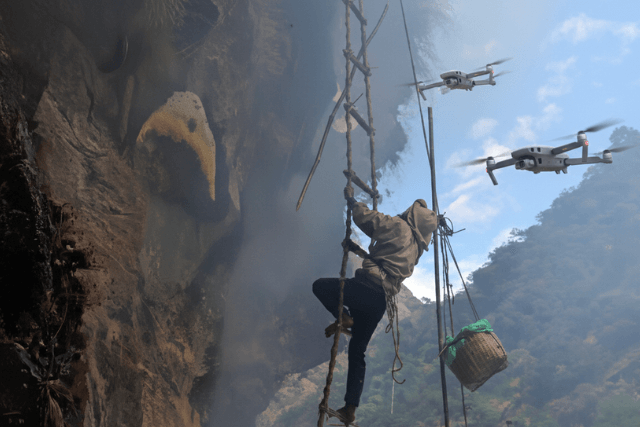

High in Nepal’s Mustang region, along the southern edge of the Tibetan Plateau, winter temperatures plunge as low as −40°C. Wind scours the land until it looks scraped raw. Vegetation retreats into survival mode. Human settlements thin out until the map itself feels unfinished.

And yet here, the Chyangra goat survives, producing a fiber so fine and insulating that European royalty once restricted its use by law.

This is not a story about fashion.

It is a story about biological extremity, and why the modern machine keeps failing to replicate it.

The Mountain That Forces Evolution

Mustang is often called a “cold desert,” but the phrase understates the violence of the climate. At elevations between 12,000 and 15,000 feet, oxygen thins, ultraviolet radiation intensifies, and winter arrives not as a season but as a siege.

For the Chyangra goat, survival here depends on a single adaptation: an emergency layer of insulation grown only when the cold becomes existential.

As temperatures collapse, the goat’s body triggers a physiological response. Beneath its coarse outer hair, known as guard hair, it grows a second coat. An ultra-fine underfleece called pashmina.

This fiber measures roughly 14 to 16 microns in diameter, up to six times thinner than human hair and significantly finer than most cashmere.

The purpose is not beauty.

The purpose is to stay alive.

Without this underfleece, the goat freezes. With it, the goat survives temperatures that kill most mammals.

This is the first truth the market often ignores.

No killing cold, no pashmina.

Why Lowland Farming Failed

As global demand for pashmina exploded, the logic of modern production followed predictably. If Chyangra goats produce the world’s finest fiber, why not farm them in gentler environments? Why not increase yield, reduce mortality, and industrialize the process?

Western agribusiness tried.

Goats were relocated to lower altitudes. Climate-controlled shelters were built. Feed was optimized. Stress was removed.

The result was not more pashmina.

It was less, or none at all.

Without the environmental trigger of extreme cold, the Chyangra goat’s body simply stopped producing the fine underfleece. The biological alarm never sounded. The emergency insulation never arrived.

Nature, it turned out, was not interested in scaling.

The machine wanted comfort.

The mountain demanded suffering.

The Nomadic System the Market Can’t Replace

Traditional Chyangra herding in Mustang is nomadic by necessity. Herders migrate seasonally, following sparse grazing routes that keep goats exposed to natural stressors: cold, wind, altitude, and scarcity.

This is not inefficient. It is precision ecology.

The goats graze on wild alpine grasses and medicinal plants unavailable in lowlands. Their diet, combined with cold stress, shapes the fiber at a molecular level, affecting softness, elasticity, and thermal performance.

This ecological principle is not unique to pashmina. Across the Himalayas, yaks raised in similarly harsh, migratory conditions produce milk used for production of himalyan dog chew that cannot be replicated by industrial systems.

Industrial feed cannot replicate this.

Climate control actively destroys it.

Every attempt to “optimize” the system removes the very conditions that make pashmina possible.

Hand-Combed or Ruined: Why Shearing Is a Crime

There is a second mistake modern production makes, quieter but equally destructive.

Machines cannot tell the difference between hair and gold.

Chyangra goats grow two distinct layers:

Guard hair, coarse and protective

Underfleece, soft, short, and insulating

Industrial shearing cuts both indiscriminately. The result is a blended fiber that looks acceptable but feels dull, itchy, and lifeless once woven.

Traditional herders do something radically slower.

In early spring, as temperatures rise slightly, the goat naturally begins to shed its underfleece. Herders hand-comb the animal, collecting only the soft pashmina while leaving the guard hair intact.

This process protects the goat, preserves fiber purity, and maintains micron-level softness.

Machines cannot feel when shedding begins.

They cannot sense resistance or release.

They cannot pause when the fiber isn’t ready.

A machine sees volume.

A herder reads the animal.

The Weaver’s Blindfold: A Story of the Fifth Sense

In a narrow alleyway just a few hundred meters from the Boudha Stupa, I sat with an elderly weaver named Maya.

Outside, the air was thick with the smell of butter lamps and the low hum of pilgrims chanting Om Mani Padme Hum. Inside her workshop, Maya’s eyes were clouded by the milky veil of advanced cataracts. Yet her shuttle moved across the loom with a speed that defied her age.

I asked her how she could possibly weave such fine, expensive fiber without being able to see the threads.

She stopped, reached out, and rubbed a tuft of raw, unspun Chyangra pashmina between her thumb and forefinger.

“The eyes are easily fooled,” she whispered, her voice barely audible over the distant ringing of prayer bells. “Silk shines. Chemicals soften. But the fingers cannot be lied to.”

She pressed the fiber gently, almost reverently.

“Machine-combed wool feels like dead hair,” she said. “Brittle, like grass in a drought. But true Chyangra, combed by a hand that knows the goat, feels like it is still carrying the animal’s heartbeat. It has a grip no machine can mimic.”

To Maya, pashmina was not a material.

It was a record.

She believed that if the goat did not suffer the cold, the wool would have no memory of warmth to give the wearer. In her world, softness was not a luxury.

It was the ghost of winter’s bite.

From Raw Fiber to Royal Fabric

Freshly combed pashmina is not immediately luxurious. It is uneven, fragile, and tangled with debris. Turning it into fabric is a slow chain of human judgment.

The fiber is first cleaned without aggressive chemicals, often using water alone. It is then spun by hand or on low-tension wheels to avoid snapping the fine strands. Weaving follows on traditional looms that allow artisans to adjust tension continuously.

Every shortcut breaks something.

High-speed spinning snaps fibers.

Chemical softening weakens structure.

Power looms flatten texture.

This is why true pashmina feels alive in the hand. It retains micro air pockets that trap heat without weight. The warmth is not bulk.

It is architecture.

Cashmere vs. Pashmina: A Necessary Distinction

The global market often collapses “cashmere” and “pashmina” into the same category. This is convenient and wrong.

Both come from goats, but their origins diverge sharply.

Cashmere is typically sourced from goats raised at lower altitudes across Mongolia, China, and Central Asia.

Pashmina, strictly speaking, comes from the Chyangra goat of the high Himalayas.

The difference is not just geography. It is stress.

Lower-altitude goats do not face lethal cold. Their underfleece is thicker and more consistent, but less insulating per gram.

Pashmina is conditional.

It exists only when the environment becomes hostile enough to demand it.

The Economics of Scarcity

A single Chyangra goat produces roughly 150 to 200 grams of usable pashmina per year.

Compare that to sheep wool, where kilograms are routine.

This scarcity is biological, not artificial.

Attempts to increase yield through selective breeding or environmental manipulation have repeatedly backfired. Push too hard and the fiber thickens. Remove stress and it disappears.

The mountain enforces limits.

This is why genuine Himalayan pashmina commands prices that confuse mass-market logic. It is not priced for effort.

It is priced for irreproducibility.

The Cultural Cost of Scaling

As demand rises, new pressures emerge.

Some producers are tempted to shear instead of comb, blend fibers silently, relocate goats to lower altitudes, or label cashmere as pashmina.

Each compromise erodes the fiber’s integrity.

More dangerously, it erodes the herding culture itself. Nomadic systems, already fragile under climate change and political borders, cannot survive if reduced to raw-material extraction.

When the mountain is treated as a factory, it eventually stops producing what made it valuable.

What Real Pashmina Represents

A true Chyangra pashmina is not just warm.

It is a record of survival.

It contains a winter that nearly killed the animal, a herder who resisted speed, a geography that refused comfort, and a system that cannot be automated.

When worn, it behaves differently. It regulates temperature instead of trapping heat. It breathes. It responds.

This is not accidental.

It is evolutionary intelligence, woven.

The KastoChha’s Verdict: Luxury Is Not Made, It Is Endured

Modern manufacturing is built on a promise: anything can be replicated with enough technology.

Chyangra pashmina breaks that promise.

No machine can simulate −40°C meaningfully. No greenhouse can substitute fear of freezing. No algorithm can tell a goat when winter is serious enough.

Luxury, in this case, is not designed.

It survived.

And as long as the Himalayas remain unwilling to cooperate with comfort, the world’s softest fabric will continue to be born where life should fail, and somehow doesn’t.